Container gantry cranes are essential pieces of equipment in modern ports, facilitating the efficient loading and unloading of shipping containers. The right container gantry crane can significantly improve the productivity and safety of your terminal operations. Choosing the right crane, however, requires a careful consideration of various factors, from your terminal’s specific needs to the crane’s technical capabilities. This article will guide you through the key considerations to help you make the best decision when selecting a container gantry crane for your terminal.

1. Understand Your Terminal’s Requirements

Before selecting a container gantry crane, it’s crucial to first assess the specific requirements of your terminal. The following factors will influence your crane selection:

a) Port Type and Size

The type and size of the port will play a significant role in determining the right container gantry crane. A large, busy port will require high-capacity cranes with faster cycle times, while smaller, less-busy terminals may need cranes with lower lifting capacities and slower operational speeds. Additionally, specialized ports such as inland terminals may require different types of cranes compared to ocean ports.

b) Cargo Volume

The expected cargo throughput, or how many containers you expect to handle per day, will influence the crane’s lifting capacity. For high-volume terminals, you will need a crane capable of handling large numbers of containers per hour without compromising on safety or reliability. For terminals with lower throughput, a smaller crane may suffice, reducing both capital expenditure and operational costs.

c) Container Size and Weight

You must also account for the size and weight of the containers that will be handled. Shipping containers come in different standard sizes, including 20-foot, 40-foot, and high-cube containers, and vary in weight depending on their contents. Choose a crane with the appropriate lifting capacity to handle the maximum weight of the containers your terminal will typically deal with.

2. Crane Type: Rail-Mounted vs. Rubber-Tyred Gantry Cranes

There are two main types of container gantry cranes commonly used in terminals: rail-mounted gantry cranes (RMG) and rubber-tyred gantry cranes (RTG). Each type offers distinct advantages depending on your terminal’s requirements.

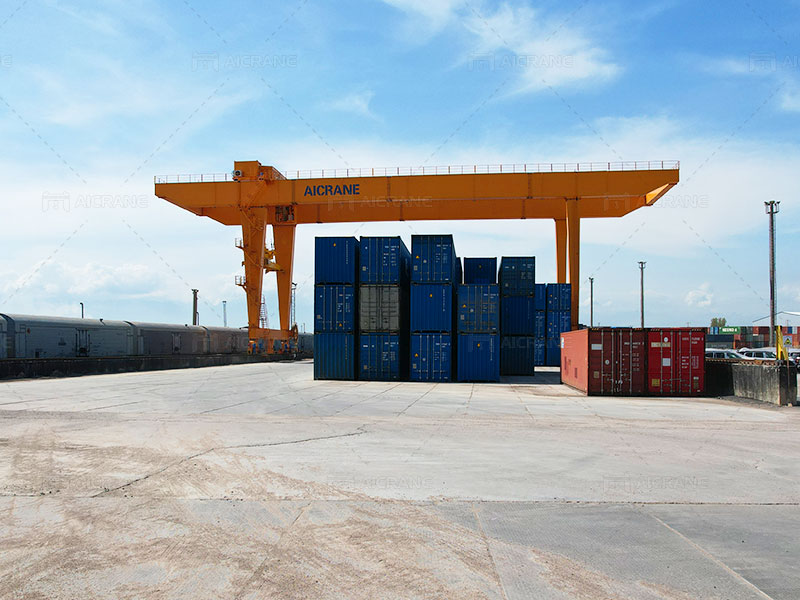

a) Rail-Mounted Gantry Cranes (RMG)

Rail-mounted gantry cranes are ideal for terminals with fixed rail infrastructure. These cranes travel along a set of rails, allowing for high precision and stability when handling containers. RMG crane is typically used in large container yards and can carry heavy containers over long distances. They are perfect for terminals with high volumes of container traffic and require minimal maneuvering.

Pros:

- Ideal for large-scale terminals with fixed rail infrastructure

- Greater stability and precision when handling containers

- Higher lifting capacities and larger spans

- Excellent for stacking containers in long rows

Cons:

- Fixed track layout limits flexibility

- Not suitable for terminals with less space or irregular layouts

b) Rubber-Tyred Gantry Cranes (RTG)

Rubber-tyred gantry cranes are designed for flexibility and mobility. These cranes are equipped with wheels, allowing them to move freely across the terminal yard without the need for a fixed rail system. RTG crane is ideal for smaller or medium-sized terminals where flexibility is more important than large-scale lifting capacity. They are also suitable for terminals with multiple stacking areas and variable container yard layouts.

Pros:

- Highly flexible and mobile

- Can be used in irregular yard layouts

- Lower installation costs (no need for rails or fixed infrastructure)

- Suitable for smaller terminals or those with space constraints

Cons:

- Generally lower lifting capacities compared to RMGs

- May require more maintenance due to mobile components

3. Lifting Capacity and Reach

When selecting a container gantry crane, the lifting capacity and reach are critical factors. The lifting capacity determines how much weight the crane can lift, while the reach refers to how far the crane’s boom can extend to pick up containers from ships.

a) Lifting Capacity

The lifting capacity should align with the types of containers your terminal will handle. Standard container gantry cranes typically have capacities ranging from 30 tons to 80 tons, with larger models available for heavy-duty operations. Consider the weight of containers, especially those that are fully loaded, and choose a crane that can handle the maximum expected weight with a safety margin.

b) Reach

The reach of a container gantry crane is important for ensuring that the crane can easily access containers on large vessels. Cranes with greater reach are required for larger ships with more extensive container stacks. The reach should be sufficient to handle the largest vessels expected at your terminal. Container gantry cranes usually have a reach of around 40-60 meters, but larger models are available for deep-water ports.

4. Speed and Efficiency

Speed and efficiency are key factors in maximizing productivity at your terminal. Container gantry cranes are designed to perform a variety of tasks, including lifting, moving, and stacking containers. The faster these tasks can be completed, the more containers your terminal can handle in a given period.

a) Hoisting Speed

Hoisting speed is the rate at which the crane’s lifting hook can move up and down. Faster hoisting speeds enable quicker container handling, reducing the time it takes to load and unload ships. However, very high hoisting speeds may come with additional wear and tear on crane components, so it’s essential to find a balance that meets your terminal’s operational needs.

b) Travel Speed

The crane’s travel speed, or how fast it can move along its track or yard, also plays an important role in terminal efficiency. Higher travel speeds allow for quicker movement between container stacks, speeding up container retrieval and storage. Consider the layout of your terminal and ensure the crane can move efficiently across the entire yard.

c) Cycle Time

Cycle time refers to the total time it takes for a crane to complete a full container-handling cycle, including the lift, move, and drop off. Shorter cycle times translate to higher productivity, which is especially important for high-volume terminals.

5. Safety Features

Safety is a top priority when selecting any heavy machinery, including container gantry cranes. Cranes used in port operations must meet stringent safety standards to prevent accidents and damage to both equipment and personnel.

a) Anti-Sway Systems

Anti-sway systems are designed to reduce the swinging motion of containers when they are being lifted and moved. This helps improve the precision of the crane’s movements and prevents accidents caused by uncontrolled swinging containers.

b) Collision Detection and Prevention

Advanced container gantry cranes are often equipped with collision detection systems to prevent accidents between cranes, containers, and other port infrastructure. These systems can detect obstacles and automatically stop the crane to avoid accidents.

c) Operator Safety Features

Modern cranes come with a variety of operator safety features, such as remote control systems, cab safety designs, and ergonomic controls. These features enhance safety by allowing operators to control the crane from a safe distance, reducing their exposure to potential hazards.

6. Maintenance and Durability

The long-term performance of your container gantry crane is highly dependent on its maintenance and durability. Buy gantry crane that is built with high-quality materials and designed for easy maintenance. It is also crucial to factor in the availability of spare parts and local service support.

a) Durability

Look for a crane that is built to withstand the harsh environment of port operations. The crane should be resistant to corrosion from saltwater and exposure to various weather conditions. Regular inspections and maintenance will ensure that the crane performs optimally for years to come.

b) Maintenance Costs

Crane maintenance can be expensive, so it’s important to choose a model that is cost-effective in terms of long-term upkeep. Look for cranes with modular designs that allow for easy repairs and upgrades. It’s also beneficial to choose cranes that have a strong local service network to reduce downtime and ensure quick support when needed.

Conclusion

Selecting the right container gantry crane for your terminal is a complex process that involves evaluating your terminal’s specific needs, crane types, lifting capacity, speed, safety features, and long-term maintenance requirements. Whether you choose a rail-mounted gantry crane or a rubber-tyred gantry crane, the goal is to improve operational efficiency while ensuring safety and reliability. By carefully considering all of these factors, you can make an informed decision that will optimize your terminal’s container handling capabilities and contribute to the overall success of your port operations.